Blueprint Machines to CNC: An Accidental Engineer-ish

This is the story I have been waiting to write.

Let me start by saying I am not a mechanical engineer by trade. I did try to become one. I had dreams of going to the CU School of Engineering in Boulder. Yeah, I didn’t get that far—too much maths, poor grades, blah. I did end up at Boulder Valley Vo-Tech studying drafting however. The domain of lead-holder pencils, tee squares, and 3-point perspectives. This was great until the blueprint machine ate my final project—a beautiful exploded diagram of a belt tensioner, ink on mylar. One copy, one beauty, everything I had, as much Kenny as I could give. Destroyed in 32 seconds. The instructor did give me an A because I literally cried. See at that time I was searching for a lot of self-worth—this belt tensioner screamed “see I can!” Fuck.

As luck would have it tho, the blueprint machine sat next to the computer lab. This lab was full raised-floor mainframe, totally state of the art at the time. It looked so fucking cool, but, uh, I wasn’t enrolled in that class. But… what about this PC sitting here? Why does it look so lonely?

The CAD instructor said it was a fresh copy of AutoCAD, and I could try it if I wanted. I would have to read up and learn on my own. Perfect! I dove in.

Fast forward a few years and I was making my living from AutoCAD. I had risen in the ranks at an Electrical Engineering firm to CAD lead. I helped write macros, develop standards, automate big print runs and such. I would ride mountain bikes, then end up at the bookstore, learning more CAD, advanced TCP/IP networking, more computers, the LISP language, and anything I could get my hands on. Sponge mode. Ride, read, work, ride, read, work. You see where this is going.

I ended up chasing a job to the Bay Area in ‘96, and about that time met my future wife. I was introduced to data engineering and databases alongside CAD. Here I was in Silicon Valley in the boom and I knew a little about some important building blocks of the technology stack at the time—and my career diverted from CAD. A blessing in most respects. I had to grow and evolve.

In the last few years however, as my day job was in pretty good shape, I started to think more about making things and building things. I decided I needed to evolve my AutoCAD knowledge into the 3D area. Technology had come so far. So I buckled down and taught myself Autodesk Fusion 360 (now just called Fusion) for 2 hours a night, 3 nights a week, for 6 months. I gobbled up every tutorial, YouTube video, Instagram feed, and online course I could. I got good, realized that wasn’t good, got better, realized I still sucked, and got even better. I am no expert, but my ideas can come out in CAD again. I can make things. Now I just needed a way for these thoughts and designs to be made in real life.

Me, learning Fusion 360

Me, learning Fusion 360

Tormach was founded in 2005 and released their first PCNC 1100 mill around 2007-2008. Since then I had always wanted to CNC stuff—machine parts from solid metal instead of just drawing them. But I didn’t have a CNC, and I didn’t have any 3D CAD knowledge. Fast forward to more recent times, and Tormach had made the PCNC 440, an affordable, smaller, garage-caliber CNC machine that could make real parts and ran on household 120V power. I convinced my wife I needed it, and… now I had a CNC. 3D printing came later—heck, you have to prototype this stuff, right? In any event, now I had the ability to think of something, design it, make it, iterate, and then finalize the design into an actual real-world thing.

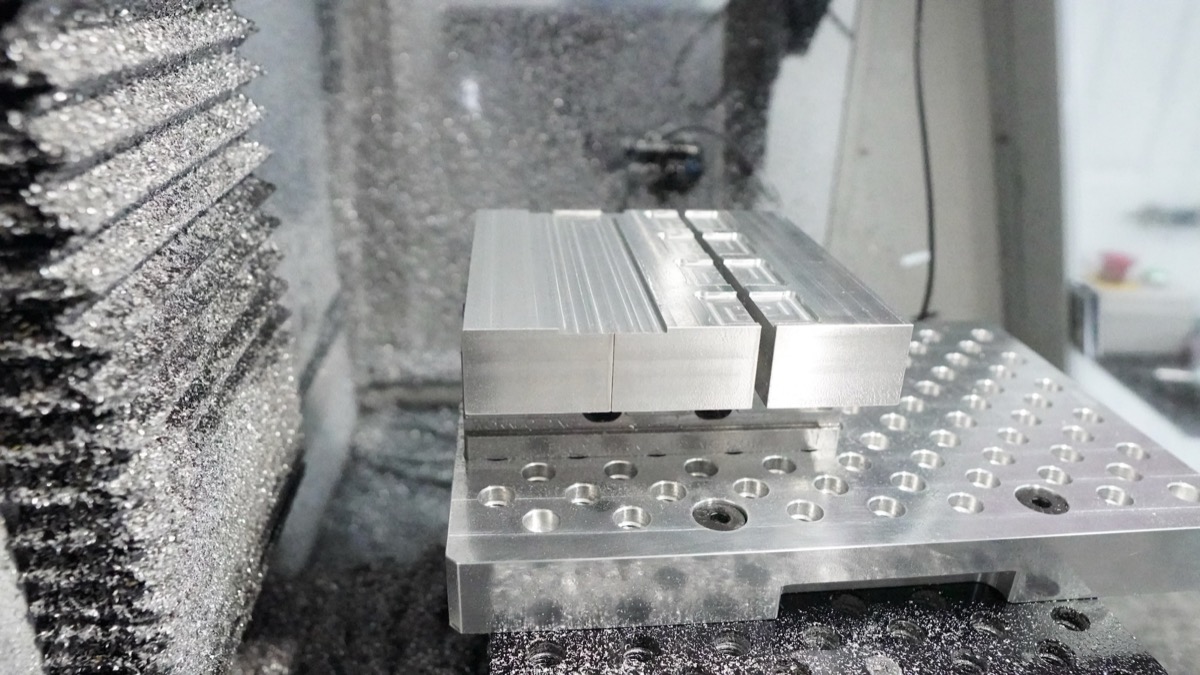

Tormach PCNC 440 running aluminum

Tormach PCNC 440 running aluminum

So this brings me back to what’s going on here at GPCX.cc. It’s probably pretty evident by now if you’ve been reading along that I am on a mission. Since that beer day in Telluride, I had just decided. That was 6 months ago now. I’ve started building.

They say the best product ideas come from your own frustrations. Yeah, no shit, but like everything frustrates me. So, does that mean I have good ideas? Probably not, actually the opposite—too much noise, not enough signal. But I’ve been working on that.

The last week I have really started to focus on what this prototype tool roll holder could be. Tool rolls are awesome—compact, organized, accessible. But there’s no good way to mount them except strapping them to the frame with ghetto straps that scratch and move. In-frame solutions are too specialized, work for some tools but not others. I hate carrying things in a backpack. On-bike storage is all the rage for a reason. I knew I could make something better.

I’ve been running a prototype for months now, first a 3D printed basic one, then fancier, still printed, then finally a combination aluminum and printed version with high-tech carbon fiber thermoplastics. The idea is, this is right before I go to production in aluminum.

Except, the product is getting worse. The fancy printed one worked flawlessly at my pre-ride at Rattler, totally solid through the chunk. Then I switched to the carbon fiber one for the actual race—because of course I did, it looked better, it was lighter, it was fancy—and the roll slipped. Not catastrophically, but enough. Enough that I noticed it at mile 15, enough that it was in my head at the end. Maybe it’s my perfectionist side, or the part of me still mad about never going to CU. But I can’t leave it well enough alone.

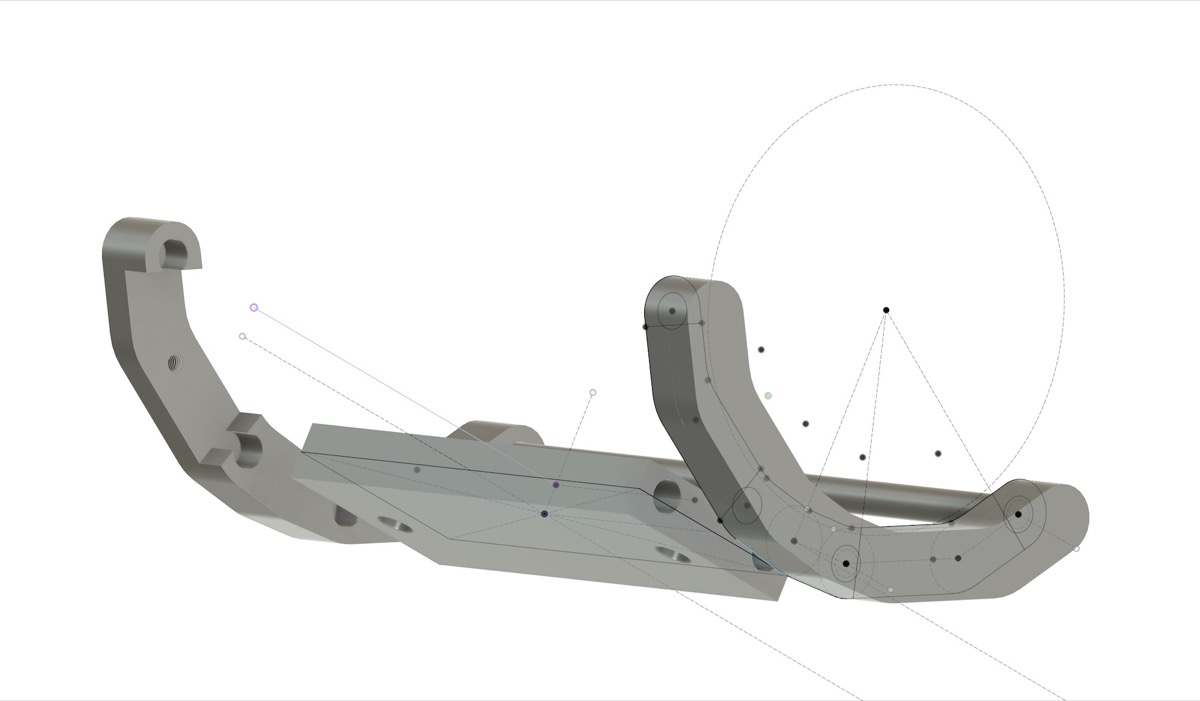

The V3 design that is worse

The V3 design that is worse

So I went back out. Took the printed one to Emma Long, let it bounce through the rocks for an hour. Solid. Took the carbon fiber one the next day. Slippy. Slight, but there. I started swapping parts between versions in the garage, mixing aluminum bits with printed bits, testing retention force with the tool roll inserted and removed 50 times in a row like some deranged QA tech. I pulled up the Fusion file and started over.

This week I’ve been feverishly iterating—changing tolerances, deleting entire features, starting over from scratch, rapidly printing tests. The hybrid design borrows the retention geometry from the printed version and the structural backbone from the CF one. In CAD it’s beautiful. On the trail? No idea yet. Let’s call this v4, we can start with that. V4 came this week, needs to be assembled, and I need to see if it works for the San Util Designs Toolsie roll that I am so fond of.

Tool Roll Holder version 1 on the Yeti sb150BR

Tool Roll Holder version 1 on the Yeti sb150BR

Let’s call this v4, we can start with that. V4 is on the printer as I write this, it needs to be assembled, and I need to see if it works for the San Util Designs Toolsie roll that I am so fond of. Maybe tomorrow’s ride, we will see.

Yeah, I’m still chasing “see I can.” That’s not some deep revelation—it’s just how I’m wired. And v4? I have no idea if it’s going to work. That’s the point. You make something, it sucks, you learn why, you make it again, it still sucks but differently, you iterate until one day it doesn’t suck anymore. Or maybe it does and you start over.

I’ve done this loop before. With pencils and mylar. With AutoCAD macros. With database schemas at 2 a.m. in the Bay Area. Same pattern, different domain. Make, break, learn, repeat.

V4 might not be the thing. Hell, v7 might not be the thing. But whatever version we land on—that’s one hell of a ride to get there.

This tool roll holding device isn’t the destination. It’s just the start.